Critical Chain Project Management (CCPM) is a project management style that takes into consideration not only the tasks but also the resources required to complete a project. The goal of CCPM is to identify the steps, timelines, and resources required to complete a project — to give you a roadmap that you can follow to ensure you complete more jobs on-time and on-budget.

What Is Project Management?

Project management is a set of tools and practices used to ensure proper planning, execution, and completion of a project or job. Project Management is an important discipline every custom manufacturer needs to master in order to efficiently and effectively plan and complete jobs in their shop.

What Is Critical Path Project Management?

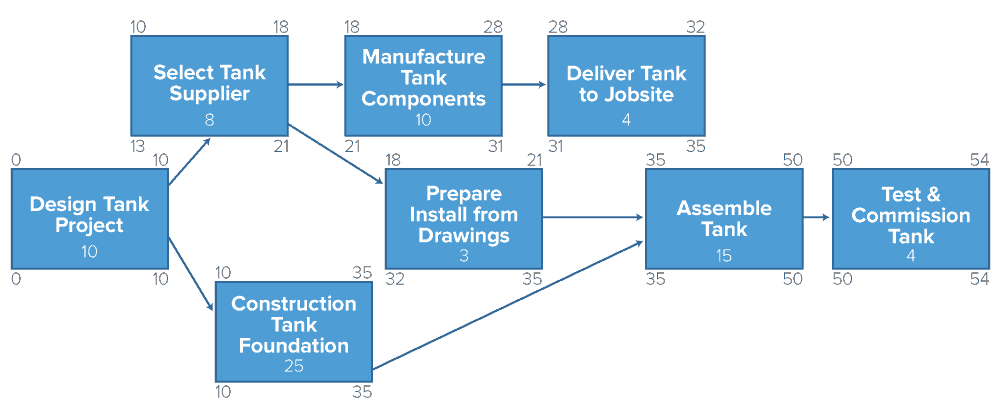

In project management, a Critical Path is the sequence of dependent tasks that form the longest duration, allowing you to determine the most efficient timeline possible to complete a project.

Identifying the critical path, i.e. what steps must be taken in order to complete a project, will help you to know how to organize your shop, and help you to plan timelines, deliverables, and milestones for your shop.

What Is Critical Chain Project Management?

Critical Chain Project Management (CCPM) is similar to the Critical Path method, in that it strives to identify the critical set of tasks, and the timeline needed to complete a project. However, CCPM takes it one step further, by taking into consideration the resources (people, equipment, physical space, materials) needed to complete the project.

A major problem with Critical Path Project Management is that while it works in theory, it fails to consider that in the real-world you do not have unlimited resources on your shop floor — you only have so many workstations, staff members, etc. — and you also have real-life constraints (i.e. bottlenecks) that exist in your shop, which determine how much work can be completed.

CCPM takes these factors into consideration to create a more holistic, and realistic, schedule for your shop.

The Critical Chain is ‘the longest path in the schedule, and considers activity interdependence and resource constraints.’ What that means is that CCPM looks at the schedule, and then determines which set of activities that, if delayed, will extend the end date of the project.

In this way, the ‘Critical Chain’ is identified, and you will pinpoint the steps and resources needed to complete a project in the fastest and most efficient manner.

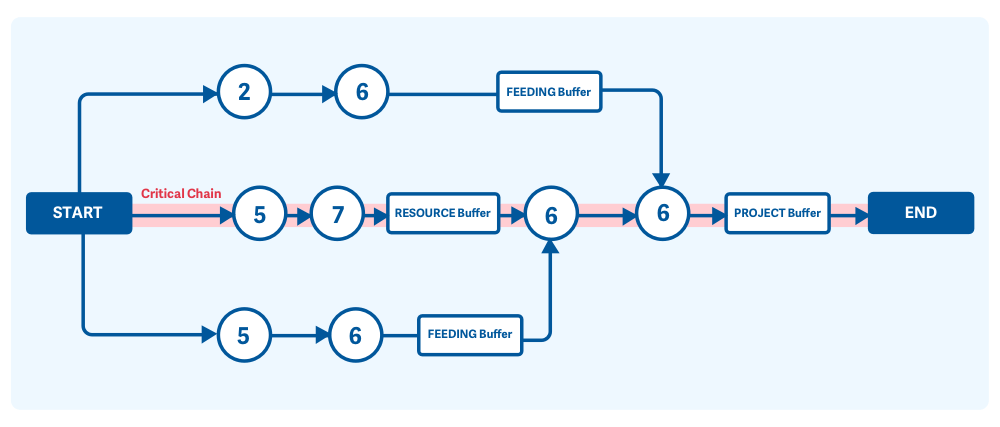

Sample Critical Chain Diagram:

(Image source: https://www.smartsheet.com/critical-path-method)

Critical Chain Project Management has its roots in Eli Goldratt’s Theory of Constraints. Much like DBR scheduling (on which our Smart Scheduling tool is based), the core of Critical Chain Project Management is your shop’s actual capacity. Instead of using theories and algorithms to determine what should be done, CCPM looks at your shop, identifies the resources needed and constraints that exist to determine what can be done.

CCPM is a method of project management that will let you complete the most jobs and function at maximum capacity.

What Is a Buffer? What Are the Different Types and How Are They Used?

Just as in DBR scheduling, CCPM relies on Buffers to ensure that the chain doesn’t break and tasks are completed to ensure on-time delivery.

Buffers are strategic safeguards inserted into the critical chain to ensure a project continues to run smoothly, and any unforeseen circumstances don’t disrupt the project delivery date.

There are typically 3 types of buffers used in CCPM:

- Project Buffers: This buffer is placed between the last task and the project completion date, and it acts as a contingency for the Critical Chain activities. Any delay along the Critical Chain will eat into this buffer, but the project completion date will not change.

- Feeding Buffers: This type of buffer is inserted between the last task on a non-critical (feeding) chain and the Critical Chain. These buffers are added to a feeding chain to ensure that any delays on a non-critical chain don’t affect the Critical Chain.

- Resource Buffers: These buffers are set on the Critical Chain to ensure appropriate resources (people, equipment) are available throughout the project when needed. These resources are commonly known as Critical Resources.

Sample Critical Chain Diagram With Buffers:

(Image source: https://activecollab.com/blog/project-management/critical-chain-project-management-ccpm)

7 Steps to Achieve Critical Chain Project Management

Many companies and organizations from Boeing, to NASA, to Texas Instruments, use CCPM to speed up their processes and ensure they complete projects on-time. Follow these seven steps to implement CCPM in your shop:

1.Identify the Critical Path

Before you can get started, you need to identify the most important tasks, as well as the tasks that will take the longest to complete. These tasks will become your critical path.

2.Determine Resource Constraints to Create the Critical Chain

Critical Chain Project Management focuses on resources — so consider any constraints you might experience as you assign employees, workstations, materials, etc. to tasks. To create your Critical Chain, you will need to determine the set of activities that, if delayed, will extend the end date of the project by looking at resource availability.

This path, along with the resource constraints it contains, is your Critical Chain. All tasks not in the critical chain are part of a feeding chain.

3.Create the As Late As Possible Schedule

Use scheduling software to create a schedule that works backward from the completion date through each activity, each starting on the latest possible start date. This is in contrast to the standard practice of starting as early as possible. This tactic will instill a sense of urgency in the project team and have them perform at the best of their abilities — and will help to prevent multitasking, which can slow your team down and reduce productivity.

4.Insert Buffers

Decide where buffers should be inserted along both the Critical Chain (resource buffers and project buffer) as well as the feeding chains (feeding buffers). You will also need to determine the appropriate size of buffer — a general rule of thumb is that the bigger the risk or uncertainty an activity entails, the bigger the buffer should be.

5.Create a Detailed Project Model

If you’re using Critical Chain methodology, you’re likely taking on a large, complicated project. To ensure timely project completion, create a detailed project model that your entire team can use. The model allows your team to see how well the project is progressing.

The project model should include time estimates, task descriptions, assigned resources, time buffers, and finish dates.

6.Eliminate Multitasking

When employees switch between different tasks, productivity drops, and task durations increase. And, ultimately, team morale decreases as your team members try to keep the project moving forward.

The Critical Chain Project Management process keeps employees focused on fewer items at a time, which allows teams to execute projects faster.

7.Oversee The Project

Continue to monitor the project, check for completed milestones to ensure the project remains on track. Manage buffers and gain the information necessary for controlling the plan — and take recovery actions if needed.

Want to learn more about how you can improve your project management and shop floor scheduling? Learn more about Genius ERP’s Smart Scheduling tool — the only DBR scheduling tool available within an ERP.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields